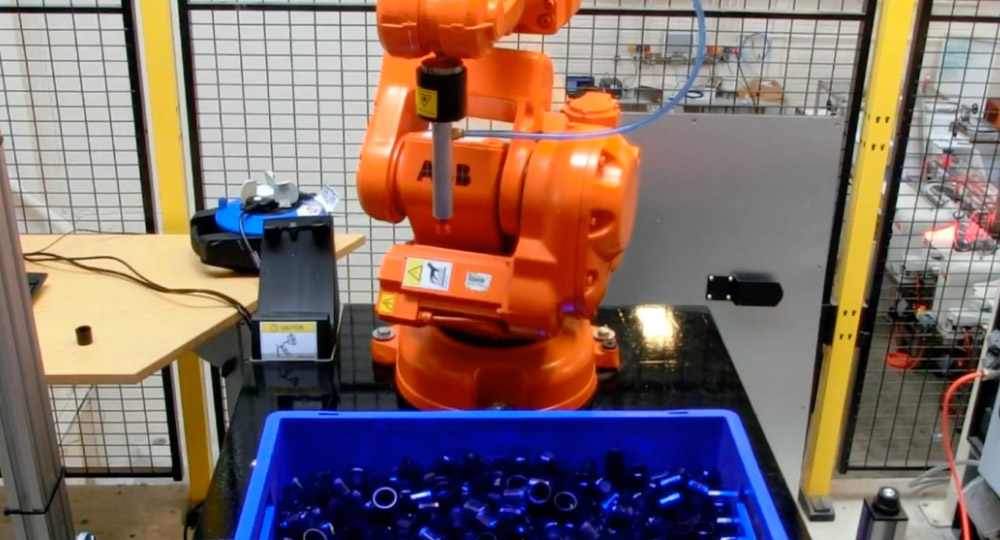

3D Bin Picking

Our expertise in 3D vision technology allows us to apply the technology to any solution that requires it. 3D vision cameras are developing rapidly, and RDS are ensuring that we have the skills and innovation to utilize these technologies to their full potential.

3D cameras can be used for a wide range of solutions including surface detection, tracking, random bin picking and more. Here at RDS, we have implemented this technology across a range of solutions.

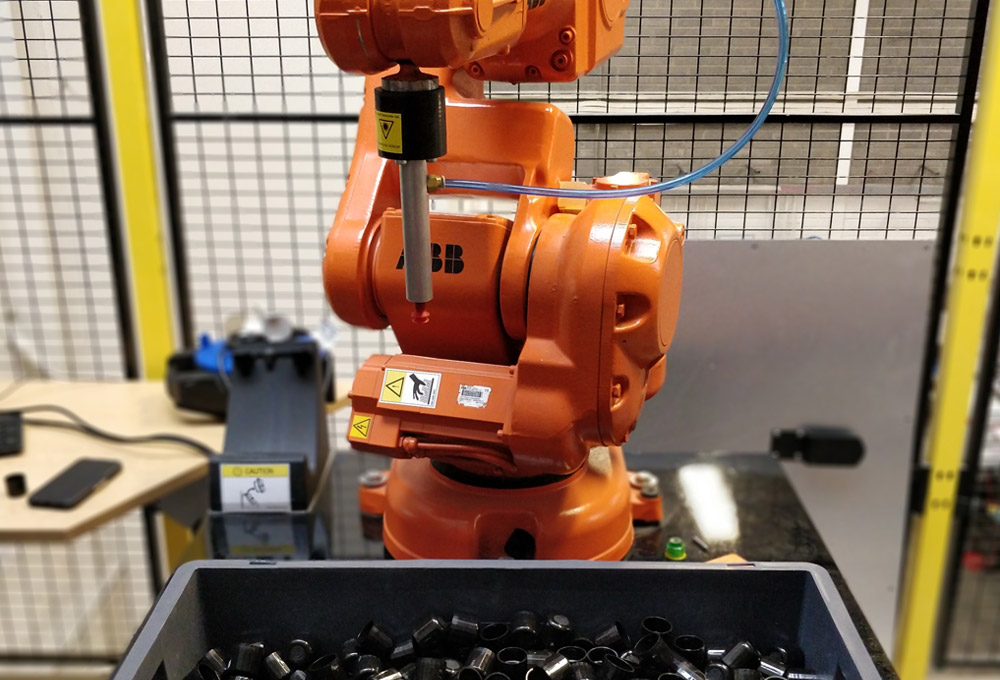

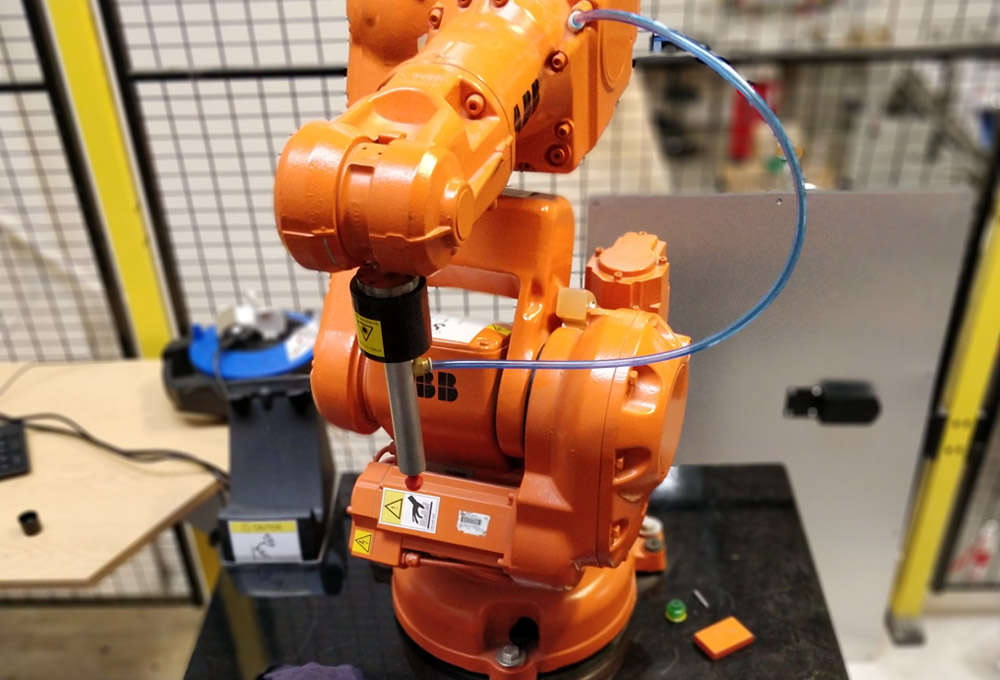

Random Bin Picking is a breakthrough in automation as it provides the industrial world with new opportunities in automating the production line. An example is as follows:

A 3D camera is set up above the pick position and totes and boxes of bins or bottles are presented beneath it. The camera captures a 3D image of the randomly sorted bins in the box and can detect not only the position of it, but also a sufficient pick surface. This then sends a signal to the robot telling it to pick the bottle on this surface and place it on an outfeed conveyor, for example. The bins can be placed on the conveyor in any required orientation.

This compact intelligent system can be introduced into any production line or assembly unit by our team of professionals in automation.

Specifications

-

Speed

Dependant on Product -

Payload

Up to 10kg -

Footprint

From 1m x 1m -

Degree of Freedom

Up to 8 axis -

Configuration

Box infeed / conveyor or packed box outfeed -

Gripper Type

Vacuum, clamp or grappler -

Control System

Allen Bradley, Siemens or Omron -

Delivery Time

From 4 weeks of final order -

Cost

Request quote