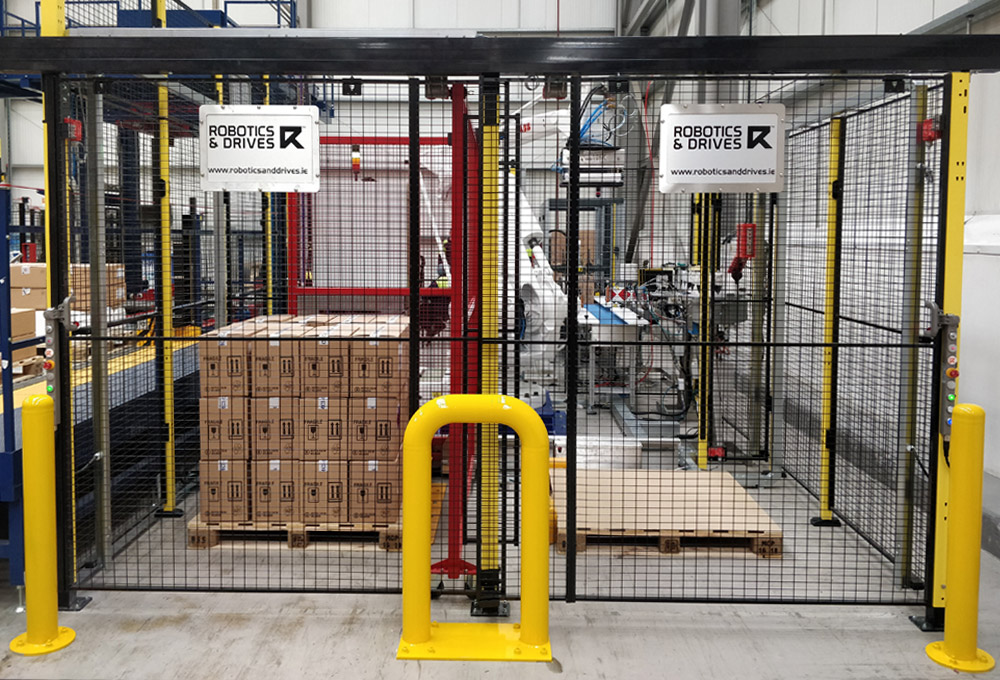

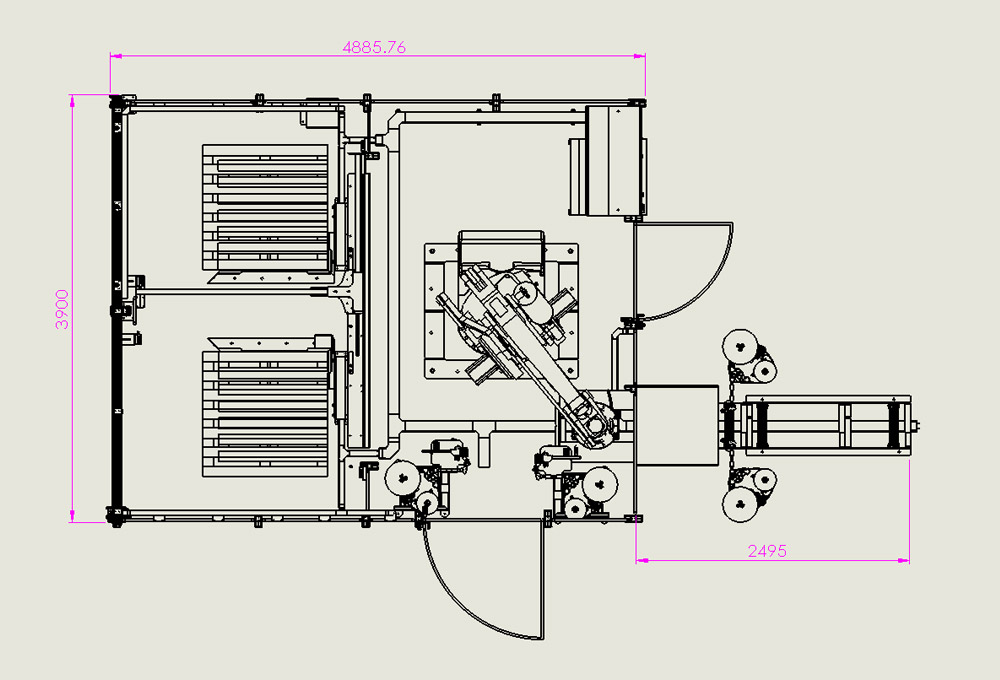

Label Application and Palletising Cell

This Robotics and Drives original design is a compact cell that provides automation to the labelling and palletising of boxed products.

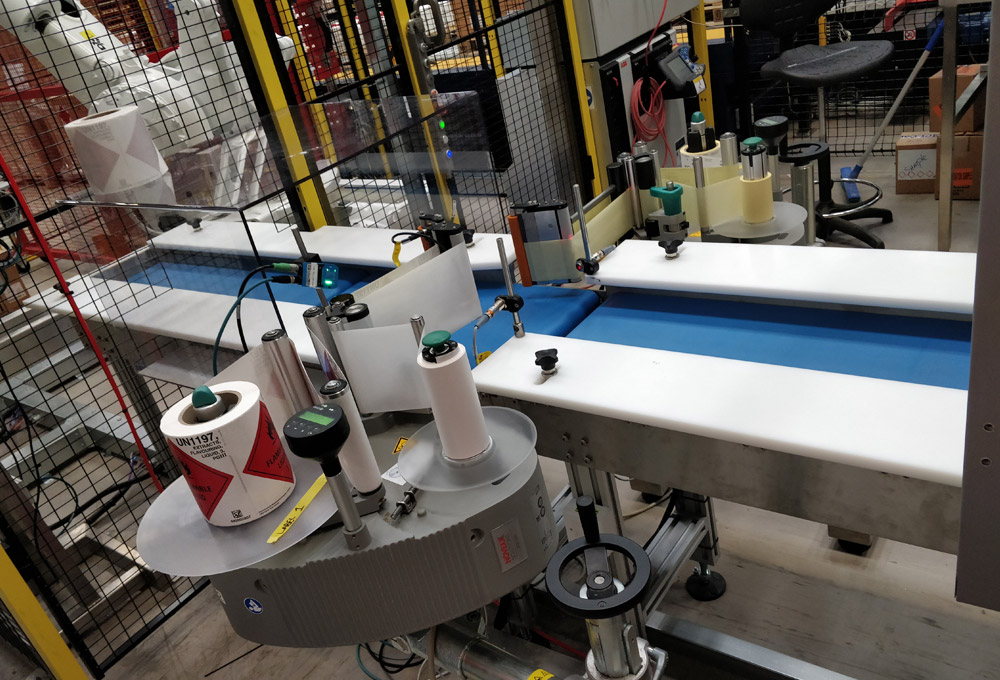

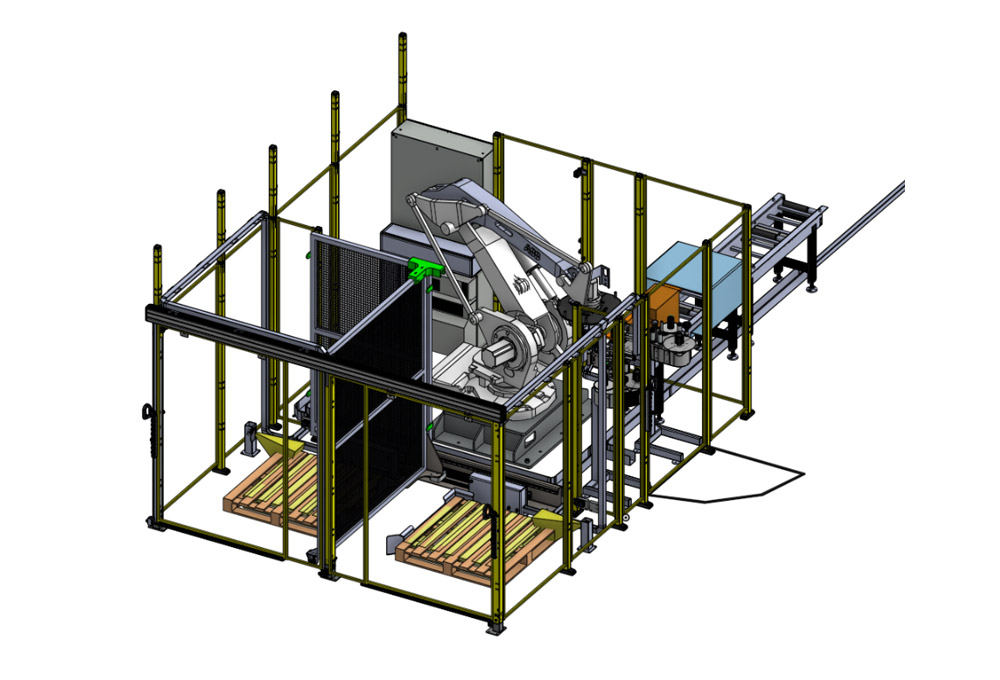

The process starts as boxes are in-fed to the system on a conveyor. Firstly they pass through two label applicators on the outskirts of the cell. When these boxes reach the robot pick position on the conveyor, the robot uses a vacuum gripper to pick the box. The robot presents the box between two parallel label applicators which have sensors to notify them when the box is present. Once the box has been labelled, it then palletises the box on one of the two pallet zones.

Through innovation, RDS designed a cell that had little or no downtime thanks to a dual pallet zone concept. A sliding door with sensors and read switches allow the full pallets to be unloaded while the robot continues to palletise in the other pallet zone. The robot is programmed to know which zone to palletise.

Safety interlock systems and lock boxes make this system a safe environment. It is programmed to only grant access when the cell is reset and immobilised.

This design has been produced with the capabilities of adopting any factory requirements and personalisation.

Specifications

-

Speed (Multiple Cases)

Up to 20 case per minute -

Payload

Max 250kg (Larger Robot Available) -

Footprint

4.8m x 3.8m -

Degree of Freedom

4 axis -

Configuration

1 product infeed, 2 pallet station -

Gripper Type

Vacuum -

Control System

Allen Bradley, Siemens or Omron -

Delivery Time

From 6-8 weeks of final order -

Cost

Request quote