Standard Palletising Cell

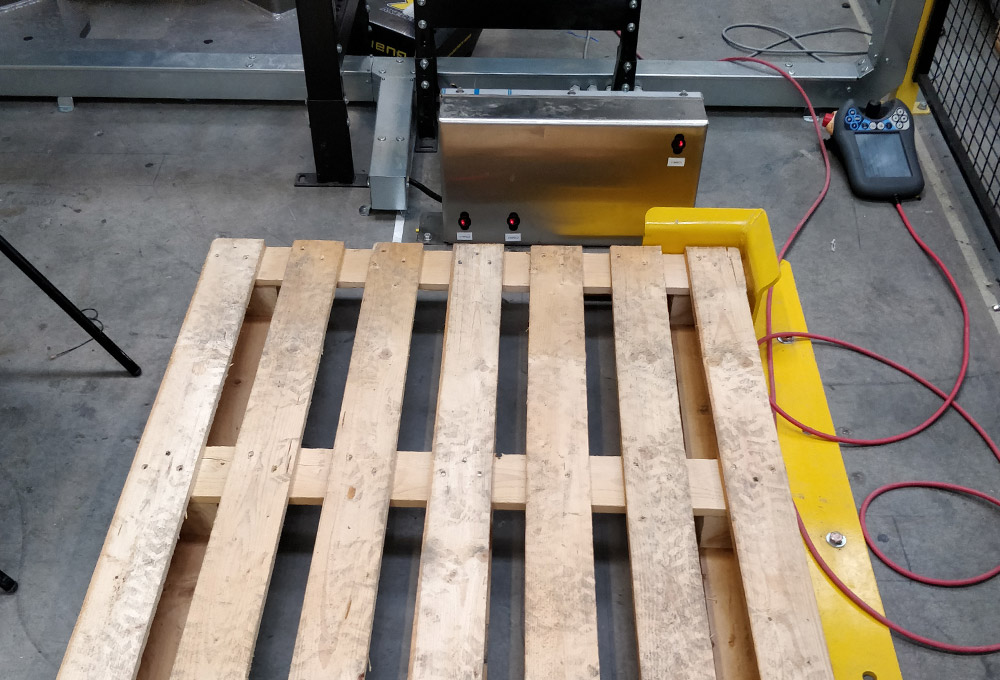

RDS have developed a standardised solution for robot palletising cells. This palletising cell uses the latest in conveyor technology and innovation in robot programming in order to palletise the boxes in the most productive and efficient way possible.

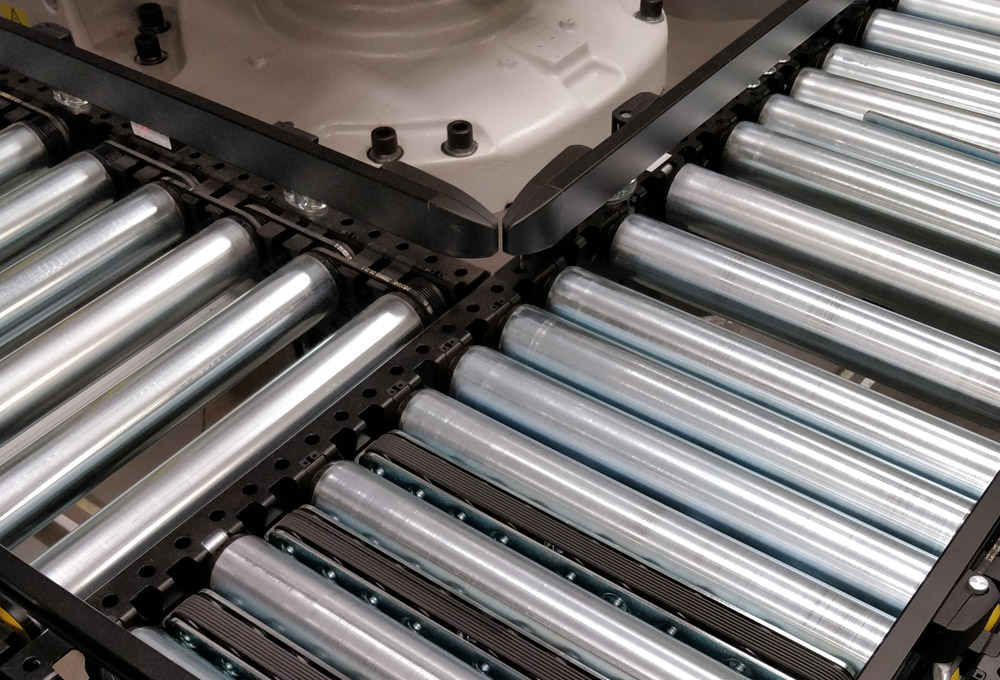

The conveyor tech in this cell allows us to alter the direction of the in-feed boxes by 90 degrees. When the boxes get to the turning point, a perpendicular drive system rises up underneath the conveyor to lift the boxes and control the movement of the boxes onto the next line. This then brings the boxes to the robot pick position, generating a signal to tell the robot to pick the box and commence palletising.

Accumulation processes are implemented on the conveyor to allow the robot to pick multiple boxes at once, providing for a more efficient system.

Multiple pick positions have also been programmed into this system to allow for a faster process.

Specifications

-

Speed (Multiple Cases)

Up to 20 cases per minute -

Payload

Max 250kg (Larger Robots Available) -

Footprint

From 4.8m x 3m -

Degree of Freedom

4 axis -

Configuration

1 product infeed, 1 pallet station -

Gripper Type

Vacuum -

Control System

Allen Bradley, Siemens or Omron -

Delivery Time

From 6 weeks of final order -

Cost

Request quote